- BLACK SCREWS

- HIGH-TENSILE FASTENERS

- INCH FASTENERS

- Button head screws UNC

- Countersunk screws UNC

- Dome nuts DIN 1587 UNC/UNF

- Flanged hex nuts DIN6923 UNC/UNF

- Hex nuts DIN 934 UNC/UNF

- Hexagon set bolts UNC/UNF

- Kep nuts UNC/UNF

- Low hex nuts DIN 439 UNC/UNF

- Nylon nuts DIN 985 UNC/UNF

- Nylon nuts low type UNC/UNF

- Socket button head UNC/UNF

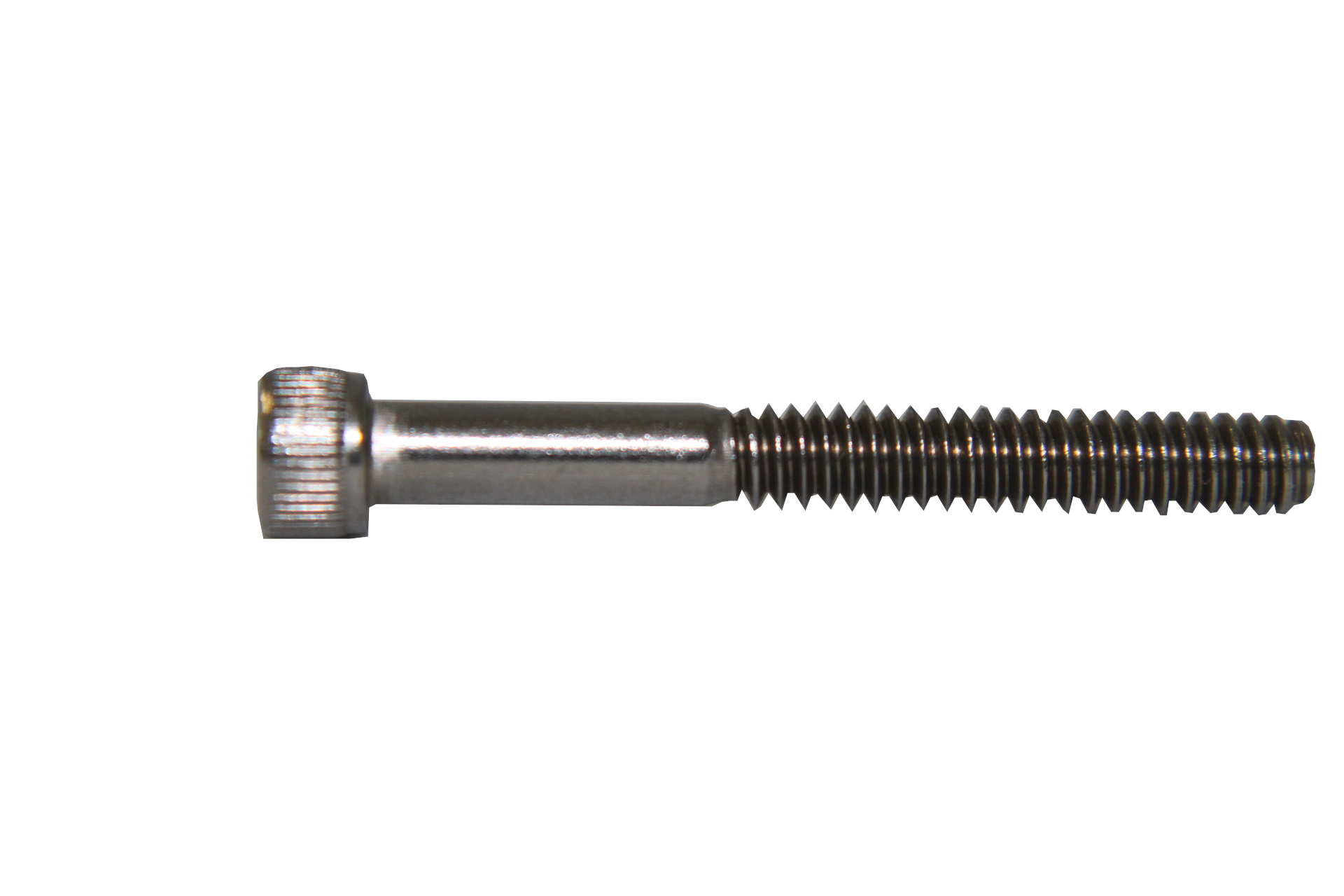

- Socket cap head screws UNC/UNF

- Socket countersunk screws UNC/UNF

- Spring washers ANSI B18.21.1

- Threaded rod DIN 976 UNC/UNF

- Washers ANSI B18.22.1

- Washers for countersunk screws

- BLACK INCH FASTENERS

- MICRO SCREWS

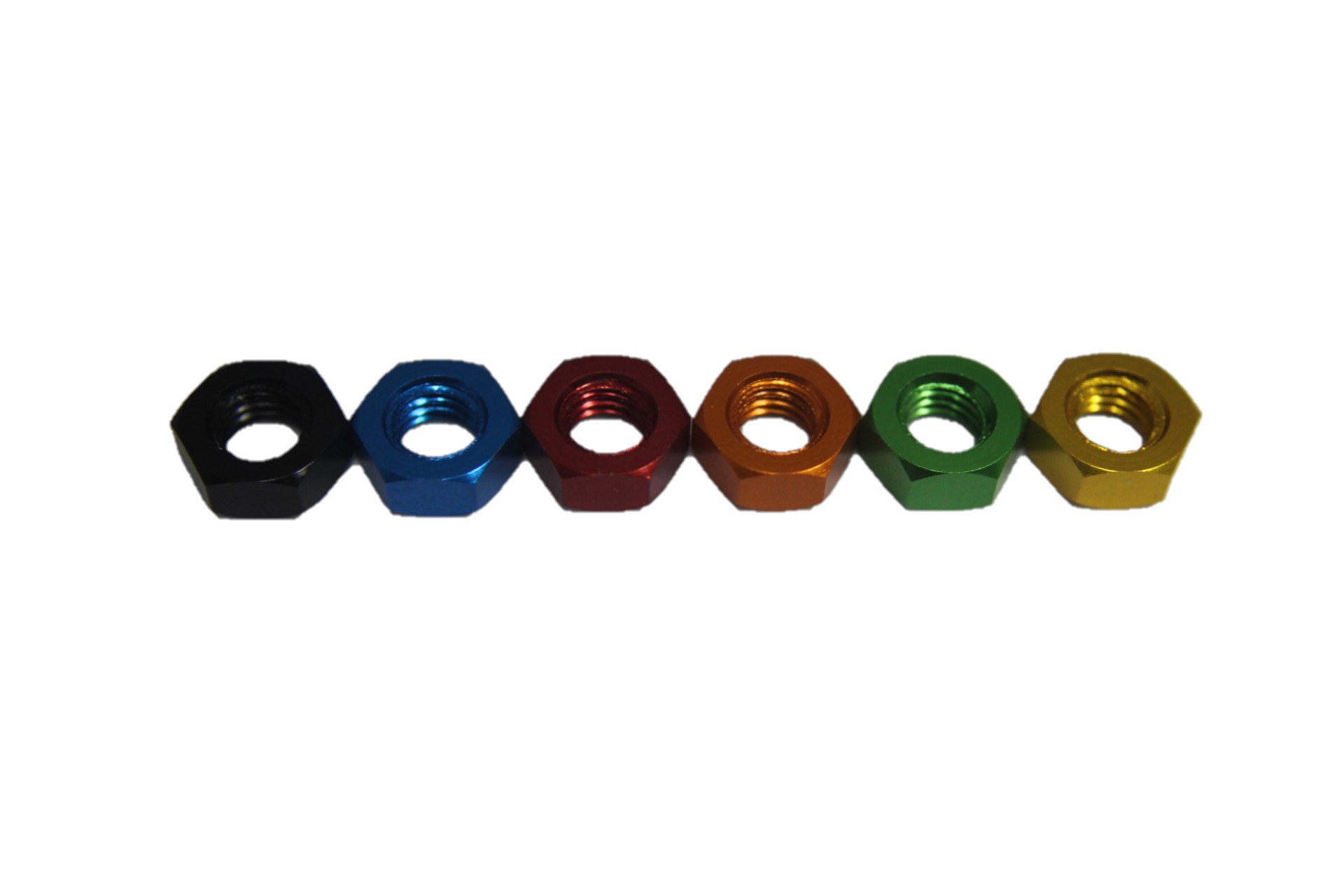

- NUTS

- Other Accessories

- WASHERS / SPRING WASHERS

- PINS/PARALLEL KEYS

- REMAINING STOCK

- SCREW ASSORTMENTS

- SCREWS AND BOLTS

- SECURITY SCREWS

- TITANIUM FASTENERS

- ALUMINIUM FASTENERS

- TOOLS

- NEW PRODUCTS

Filter

–

Socket cap head screws UNC/UNF

more articles in this category

1 Stück Zollschraube Zylinderkopf Gr.5 1/4"-20X1 1/2"

Innensechskantschrauben mit Zylinderkopf Titan Gr.5 Material 3.7165 1 Stück ähnlich DIN 912 UNC 1/4"-20X1 1/2"

€8.99*

1 Stück Zollschraube Zylinderkopf Gr.5 1/4"-20X1 1/4"

Innensechskantschrauben mit Zylinderkopf Titan Gr.5 Material 3.7165 1 Stück ähnlich DIN 912 UNC 1/4"-20X1 1/4"

€8.29*

1 Stück Zollschraube Zylinderkopf Gr.5 1/4"-20X1"

Innensechskantschrauben mit Zylinderkopf Titan Gr.5 Material 3.7165 1 Stück ähnlich DIN 912 UNC 1/4"-20X1"

€7.69*

1 Stück Zollschraube Zylinderkopf Gr.5 1/4"-20X1/2"

Innensechskantschrauben mit Zylinderkopf Titan Gr.5 Material 3.7165 1 Stück ähnlich DIN 912 UNC 1/4"-20X1/2"

€6.99*

1 Stück Zollschraube Zylinderkopf Gr.5 1/4"-20X3/4"

Innensechskantschrauben mit Zylinderkopf Titan Gr.5 Material 3.7165 1 Stück ähnlich DIN 912 UNC 1/4"-20X3/4"

€6.99*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 5/8"-11X5 1/2"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 5/8"-11X5 1/2"

€27.59*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 1/2"-13X1 1/2"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 1/2"-13X1 1/2"

€5.59*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 1/2"-13X1 1/4"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 1/2"-13X1 1/4"

€4.99*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 1/2"-13X1 3/4"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 1/2"-13X1 3/4"

€5.59*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 1/2"-13X1"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 1/2"-13X1"

€4.99*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 1/2"-13X2 1/4"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 1/2"-13X2 1/4"

€6.29*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 1/2"-13X2 3/4"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 1/2"-13X2 3/4"

€6.99*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 1/2"-13X2"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 1/2"-13X2"

€6.29*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 1/2"-13X3 1/2"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 1/2"-13X3 1/2"

€9.79*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 1/2"-13X3"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 1/2"-13X3"

€7.69*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 1/2"-13X3/4"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 1/2"-13X3/4"

€4.19*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 1/2"-13X4"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 1/2"-13X4"

€12.49*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 1/2"-13X5/8"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 1/2"-13X5/8"

€6.99*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 5/8"-11X1 1/2"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 5/8"-11X1 1/2"

€13.79*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 5/8"-11X1 1/4"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 5/8"-11X1 1/4"

€12.49*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 5/8"-11X1 3/4"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 5/8"-11X1 3/4"

€14.59*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 5/8"-11X1"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 5/8"-11X1"

€11.79*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 5/8"-11X2 1/2"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 5/8"-11X2 1/2"

€16.59*

1 Stück Zylinderkopfschraube ähnl. DIN 912 A2 5/8"-11X2 1/4"

Innensechskantschrauben mit Zylinderkopf Edelstahl rostfrei A2 1 Stück ähnlich DIN 912 UNC 5/8"-11X2 1/4"

€15.99*